pH Meter India, LAB pH METER, ECONOMY

LAB pH METER, ECONOMY

CpH-101

Contech CpH-101 Bench top pH Meter is an economy model for the measurement of pH incorporating latest electronic design coupled with reliable electro chemical sensor. These economy pH Meters cover innumerable applications in Education, Chemical, Food processing, Cosmetic, Biological & Agricultural fields.

Features

Specifications:

| Model | CpH-101 | CpH-102 | CpH-103 |

| pH Range | 0-14pH | 0-14pH | -2.0000~19.999pH |

| pH Resolution | 0.01pH | +0.01pH | 0.001pH |

| pH Accuracy | +0.02pH | + 0.002pH | +0.002pH |

| Temperature compensation | Manual | Automatic or Manual | Automatic or Manual |

| Temperature range | 0~100o C | 0~100o C | 0~100o C |

| mV Range | +1999mV | 0.1mV+1999mV | +1999.9mV |

| mV Resolution | 1mV | 1mV | 0.1mV |

| mV Accuracy | +2mV +1mV | +1mV | +0.5mV |

| Electrode |

pH combination electrode - Plastic- EpHP01 |

pH combination electrode with built in temperature sensor - Plastic-EpHP02 |

pH combination electrode - Glass -EpHG03 |

| Temperature Electrode | --- | Built in | Temperature sensor electrode |

| Meter Dimensions (mm) | 175 (L) x 140 (D) x 55 (H) | 165 (L) x 190 (D) x 60 (H) | 165 (L) x 190 (D) x 60 (H) |

| Meter Weight | 600 g | 700 g | 700 g |

LAB pH METER, PRECISION pH, mv, oC

CpH-102 & CpH-103

Contech CpH -102, an advanced Bench top pH Meter is the perfect combination of the state of the art electronic design coupled with advanced software & reliable electro chemical sensor higher uses a combination plastic pH electrode with inbuilt temperature sensor for the simultaneous measurements of pH & temperature & automatic temperature correction. CpH-103, a higher end bench pH Meter incorporates a glass electrode & seperate temperature sensor for high accuracy pH measurement & automatic temperature compensation.

These pH Meters cover innumerable applications in Research, Education, Chemical, Pharmaceutical, Food processing, Cosmetic, Biological & Agricultural fields.

Specifications:

| Model | CpH-101 | CpH-102 | CpH-103 |

| pH Range | 0-14pH | 0-14pH | -2.0000~19.999pH |

| pH Resolution | 0.01pH | +0.01pH | 0.001pH |

| pH Accuracy | +0.02pH | +0.002pH | +0.002pH |

| Temperature compensation | Manual | Automatic or Manual | Automatic or Manual |

| Temperature range | 0~100o C | 0~100o C | 0~100o C |

| mV Range | +1999mV | 0.1mV+1999mV | +1999.9mV |

| mV Resolution | 1mV | 1mV | 0.1mV |

| mV Accuracy | +2mV +1mV | +1mV | +0.5mV |

| Electrode |

pH combination electrode - Plastic- EpHP01 |

pH combination electrode with built in temperature sensor - Plastic-EpHP02 |

pH combination electrode - Glass -EpHG03 |

| Temperature Electrode | --- | Built in | Temperature sensor electrode |

| Meter Dimensions (mm) | 175 (L) x 140 (D) x 55 (H) | 165 (L) x 190 (D) x 60 (H) | 165 (L) x 190 (D) x 60 (H) |

| Meter Weight | 600 g | 700 g | 700 g |

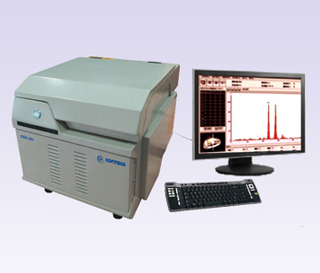

GAS PROPORTIONAL XRF DETECTOR CGX-101

XRF is used to detect and analyze noble metals like Gold ( Au), Silver (Ag), Platinum (Pt), Iridium (Ir), Osmium (Os), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Copper (Cu), Zinc (Zn), Nickel (Ni), Cadmium (Cd), Iron (Fe), Cobalt (Co), Indium (In), Tin (Sn), in the Jewellery Industry.

Energy Dispersive X-ray Fluorescence (EDXRF) technique relies on the detector and the detection circuit capability to resolve spectral peaks due to different energy X-Rays emitted when a primary X-Ray beam strikes a metal alloy corresponding to different elements in the sample, intensity of the spectrum radiation proportional to the concentration of element. The spectrum is then processed through the powerful computer software which calculates and reports the various elements & their composition in the sample.

XRF Gold Purity Tester consists of X-Ray tube, high voltage power supply for X-Ray source, X-Ray tube filters, X-Ray fluorescence Detector, processing electronics and system interface & an external computer. A camera is incorporated in the system to view the sample on the computer screen.

XRF is a reference technique, hence standards are required for quantitative results. Standards are analyzed, spectral intensities generated are used to obtain a intensity v/s concentration plot for calibration. This calibration is used to evaluate the spectral intensities of unknown samples.

How to get best results from XRF Spectrometer :

Specifications:

| Detectable elements | : | Iron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), Zinc (Zn), Ruthenium (Ru), Rhodium (Rh), Palladium (Pd), : Silver (Ag), Cadmium( Cd), Indium (In), Tin (Sn), Osmium (Os), Iridium (Ir), Platinum (Pt), Gold (Au) |

| Measurement Results | : | Cu (Combined with Fe, Co, Ni, Zn), Ag (Combined with Ru, Rh, Pd, Cd, In, Sn), Au (Combined with Os, Ir, Pt) |

| Accuracy of measurement | : | +0.3% (Molten Metal above 90% Au) +0.5% (Molten Metal below 90% Au) : +1% (Molten Metal below 50% Au) |

| Sensor | : | Gas Proportional Counter |

| Cooling for Detector | : | Air |

| Detection Range | : | 1%-----99.99% |

| Testing Time | : | 30-----200 secs |

| Test Spot Area | : | 0.3mm |

| Power supply | : | 200-240V AC, 50/60Hz |

| Power rating | : | 130 Watt |

| Working Temperature | : | 15-25°C |

| Relative humidity | : | <70% |

| Operation atmosphere | : | Vibration free surface and air conditioned room |

| Interface for Computer | : | Inbuilt (External Monitor, Keyboard required) |

| Software for Operation | : | Menu Driven User Friendly Operating System |

| Dimensions of Instrument | : | Length : 450mm Width : 350mm Height : 345mm (with test compartment cover in : closed position) & 565mm (in open position) |

| Dimensions of Sample Chamber | : | Length : 300mm Width : 255mm Height : 80mm |

| Net Weight | : | 30kg |

SILICON - PIN XRF DETECTOR CGX-102

XRF is used to detect and analyze noble metals like Gold ( Au), Silver (Ag), Platinum (Pt), Iridium (Ir), Osmium (Os), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Copper (Cu), Zinc (Zn), Nickel (Ni), Cadmium (Cd), Iron (Fe), Cobalt (Co), Indium (In), Tin (Sn), in the Jewellery Industry.

Energy Dispersive X-ray Fluorescence (EDXRF) technique relies on the detector and the detection circuit capability to resolve spectral peaks due to different energy X-Rays emitted when a primary X-Ray beam strikes a metal alloy corresponding to different elements in the sample, intensity of the spectrum radiation proportional to the concentration of element. The spectrum is then processed through the powerful computer software which calculates and reports the various elements & their composition in the sample.

XRF Gold Purity Tester consists of X-Ray tube, high voltage power supply for X-Ray source, X-Ray tube filters, X-Ray fluorescence Detector, processing electronics and system interface & an external computer. A camera is incorporated in the system to view the sample on the computer screen.

XRF is a reference technique, hence standards are required for quantitative results. Standards are analyzed, spectral intensities generated are used to obtain a intensity v/s concentration plot for calibration. This calibration is used to evaluate the spectral intensities of unknown samples..

How to get best results from XRF Spectrometer :

Specifications:

| Detectable elements | : | Titanium to Uranium |

| Measurement Results | : | ron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), Zinc (Zn), Ruthenium (Ru), Rhodium (Rh), Palladium (Pd), Silver (Ag), Cadmium( Cd), Indium (In), Tin (Sn), Osmium (Os), Iridium (Ir), Platinum (Pt), Gold (Au) -all metals separately. |

| Accuracy of measurement | : | +0.15% (Molten Metal above 90% Au) +0.3% (Molten Metal below 90% Au) +0.5% (Molten Metal below 50% Au) * Sensor : Silicon-Pin Diode (Silicon Drift Semiconductor or CGX-103) |

| Sensor | : | Gas Proportional Counter |

| Cooling for Detector | : | Thermoelectric |

| Detection Range | : | 1%-----99.99% |

| Testing Time | : | 30-----200 secs |

| Test Spot Area | : | 0.5mm |

| Power supply | : | 90-240 V AC, 50/60HZ |

| Power rating | 30 Watt | |

| Working Temperature | 15-25°C | |

| Relative humidity | <70% | |

| Operation atmosphere | Vibration free surface and air conditioned room | |

| Interface for Computer | Inbuilt (External Monitor, Keyboard required) | |

| Software for Operation | Menu Driven User Friendly Operating System | |

| Dimensions of Instrument | Length : 335mm Width : 225mm Height : 210mm (with test compartment cover in : closed position) & 565mm (in open position) | |

| Dimensions of Sample Chamber | Length : 235mm Width : 195mm Height : 80mm | |

| Net Weight | 12kg |

SILICON DRIFT DETECTORS CGX-103

SDD in place of Si-Pin Detector for enhanced performance & Detection (Spectral Resolution)

Specifications:

| Detectable elements | : | Titanium to Uranium |

| Measurement Results | : | ron (Fe), Cobalt (Co), Nickel (Ni), Copper (Cu), Zinc (Zn), Ruthenium (Ru), Rhodium (Rh), Palladium (Pd), Silver (Ag), Cadmium( Cd), Indium (In), Tin (Sn), Osmium (Os), Iridium (Ir), Platinum (Pt), Gold (Au) -all metals separately. |

| Accuracy of measurement | : | The Accuracy of measurement is better than Silicon-pin Detector |

| Sensor | : | Silicon Drift Detector is used in the place of Silicon-Pincode Detector for Enhanced performance & spectral resolutions. |

| Cooling for Detector | : | Thermoelectric |

| Detection Range | : | 1%-----99.99% |

| Testing Time | : | 30-----200 secs |

| Test Spot Area | : | 0.5mm |

| Power supply | : | 90-240 V AC, 50/60HZ |

| Power rating | 30 Watt | |

| Working Temperature | 15-25°C | |

| Relative humidity | <70% | |

| Operation atmosphere | Vibration free surface and air conditioned room | |

| Interface for Computer | Inbuilt (External Monitor, Keyboard required) | |

| Software for Operation | Menu Driven User Friendly Operating System | |

| Dimensions of Instrument | Length : 335mm Width : 225mm Height : 210mm (with test compartment cover in : closed position) & 565mm (in open position) | |

| Dimensions of Sample Chamber | Length : 235mm Width : 195mm Height : 80mm | |

| Net Weight | 12kg |

HANDHELD DETECTORS (Si-PIN / SDD) CGX-104

XRF is used to detect and analyze noble metals like Gold ( Au), Silver (Ag), Platinum (Pt),Iridium (Ir), Osmium (Os), Palladium (Pd), Rhodium (Rh), Ruthenium (Ru), Copper (Cu), Zinc (Zn), Nickel (Ni), Cadmium (Cd), Iron (Fe), Cobalt (Co), Indium (In), Tin (Sn), in the Jewellery Industry.

Energy Dispersive X-ray Fluorescence (EDXRF) technique relies on the detector and the detection circuit capability to resolve spectral peaks due to different energy X-Rays emitted when a primary X-Ray beam strikes a metal alloy corresponding to different elements in the sample, intensity of the spectrum radiation proportional to the concentration of element. The spectrum is then processed through the powerful computer software which calculates and reports the various elements & their composition in the sample.

XRF Gold Purity Tester consists of X-Ray tube, high voltage power supply for X-Ray source,X-Ray tube filters, X-Ray fluorescence Detector, processing electronics and system interface& an external computer. A camera is incorporated in the system to view the sample on the computer screen.

XRF is a reference technique, hence standards are required for quantitative results. Standards are analyzed, spectral intensities generated are used to obtain a intensity v/s concentration plot for calibration. This calibration is used to evaluate the spectral intensities of unknown samples.

How to get best results from XRF Spectrometer :

Specifications:

| X-ray tube | : | Tungsten anode, 40 kV , 100 µA with 5 filter positions |

| Detector type | : | solid state Si-pin-diode with thermo-electrical cooling (optional SDD) |

| Active area | : | 6 mm2 |

| Energy resolution | : | <165 eV at 5.9 keV (<140 eV for SDD) |

| Display | : | High resolution 4 inch color touch-screen Supported operating |

| Supported operating systems | : | Windows CE/Mobile for PDA Windows XP/Vista/7 for PC |

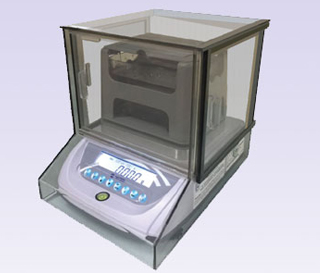

GOLD PURITY CHECKING BALANCE

Specifications:

| Models | CT-300 | Ct-600 |

| Capacity | 300g | 600g |

| Accuracy | 0.01g | 0.01g |

| Density Accuracy | 0.01 g/cc | 0.01 g/cc |